Commonly used conductive agents for lithium-ion batteries can be divided into traditional conductive agents (such as carbon black, conductive graphite, carbon fiber, etc.) and new conductive agents (such as carbon nanotubes, graphene and their mixed conductive pastes, etc.). The types of conductive agents on the market are SPUERLi, S-O, KS-6, KS-15, SFG-6, SFG-15, 350G, acetylene black (AB), Ketjen black (KB), vapor grown carbon fiber (VGCF) , carbon nanotubes (CNTs), etc.

1. Carbon black

Carbon black is chain-like or grape-like under scanning electron microscope, and a single carbon black particle has a very large specific surface area (700m2/g). The high specific surface area and tight packing of carbon black particles facilitates the close contact between the particles, forming a conductive network in the electrode. The process problem caused by the larger specific surface is that it is difficult to disperse and has strong oil absorption. This requires improving the dispersibility by improving the mixing process of active substances and conductive agents, and controlling the amount of carbon black within a certain range. (usually below 1.5%).

2. Conductive graphite

Conductive graphite also has good electrical conductivity, its own particles are closer to the particle size of active material particles, and the particles are in the form of point contact, which can form a conductive network structure of a certain scale, which can improve the conduction rate while being used for negative electrodes. It can also improve the negative electrode capacity.

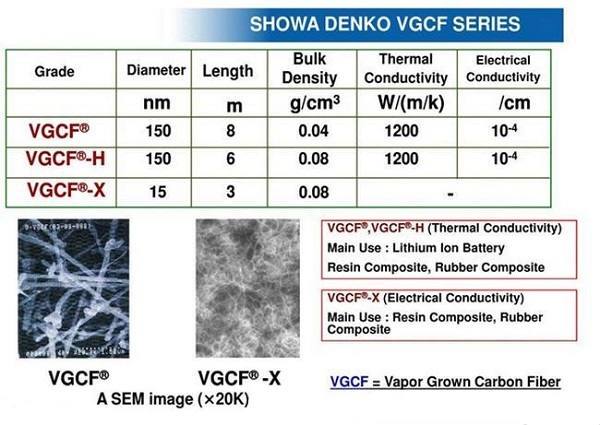

3. Carbon fiber (VGCF)

Conductive carbon fiber has a linear structure, and it is easy to form a good conductive network in the electrode, showing good conductivity, thereby reducing electrode polarization, reducing battery internal resistance and improving battery performance. In the battery with carbon fiber as the conductive agent, the contact form between the active material and the conductive agent is point-line contact. Compared with the point-to-point contact form between conductive carbon black and conductive graphite, it not only helps to improve the conductivity of the electrode, but also reduces the amount of conductive agent. Increase battery capacity. The comparison of the dispersion state of VGCF and conductive carbon black in the active material is shown in Figure 2:

4. Carbon Nanotubes (CNTs)

CNTs can be divided into single-walled CNTs and multi-walled CNTs. Carbon nanotubes with a one-dimensional structure are similar to fibers and have a long column shape with a hollow interior. The use of carbon nanotubes as a conductive agent can better form a complete conductive network, which is also in point-line contact with the active material. It is related to improving battery capacity (improving the compaction density of the pole piece), rate performance, battery cycle life and reducing Cell interface impedance is of great use. At present, some products of BYD and AVIC lithium battery use CNT as a conductive agent, which has a good effect after the reaction. Carbon nanotubes can be divided into two growth states: entangled and arrayed. No matter which form is used in lithium-ion batteries, there is a problem of dispersion. At present, it can be made into dispersion slurry by high-speed shearing, adding dispersant, and materials, ultra-fine grinding beads electrostatic dispersion and other processes to solve.

5. Graphene

As a new type of conductive agent, due to its unique sheet-like structure (two-dimensional structure), the contact with the active material is a point-to-surface contact instead of a conventional point-to-point contact, which can maximize the use of the conductive agent and reduce the The amount of conductive agent can be used to increase the capacity of lithium-ion batteries by using more active materials. However, due to its high cost, difficult dispersion, and the disadvantages of hindering lithium ion transport, it has not been fully industrialized.

6. Binary and ternary conductive paste

In the latest research progress, the conductive agent selected for some lithium-ion batteries is a mixed slurry of two or three of CNT, graphene, and conductive carbon black. It is the demand of industrial application to compound conductive agents into conductive paste, and it is also the result of mutual coordination and stimulating use of conductive agents. Whether it is carbon black, graphene or CNT, it is very difficult to disperse the three when they are used alone. If you want to mix them evenly with the active material, you must disperse them before stirring the electrode slurry. Then put into use.